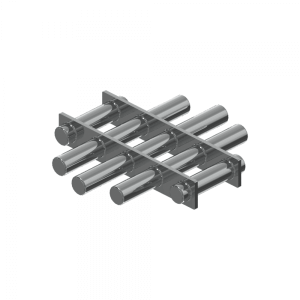

Grid Separator

Product Specification:

- Material 316L / 304L

- Size and shape to suit application

- Hygienic design

- Min. Fe-particle size that can be caught 30 µm

- Max. operating temperature 60 °C (Higher temp designs available)

- Surface Finish Dull polish (standard) other finishes available

- Field strength (flux density) on tube (±5%) 7000, 9000 or 12000 gauss

Product Information:

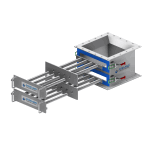

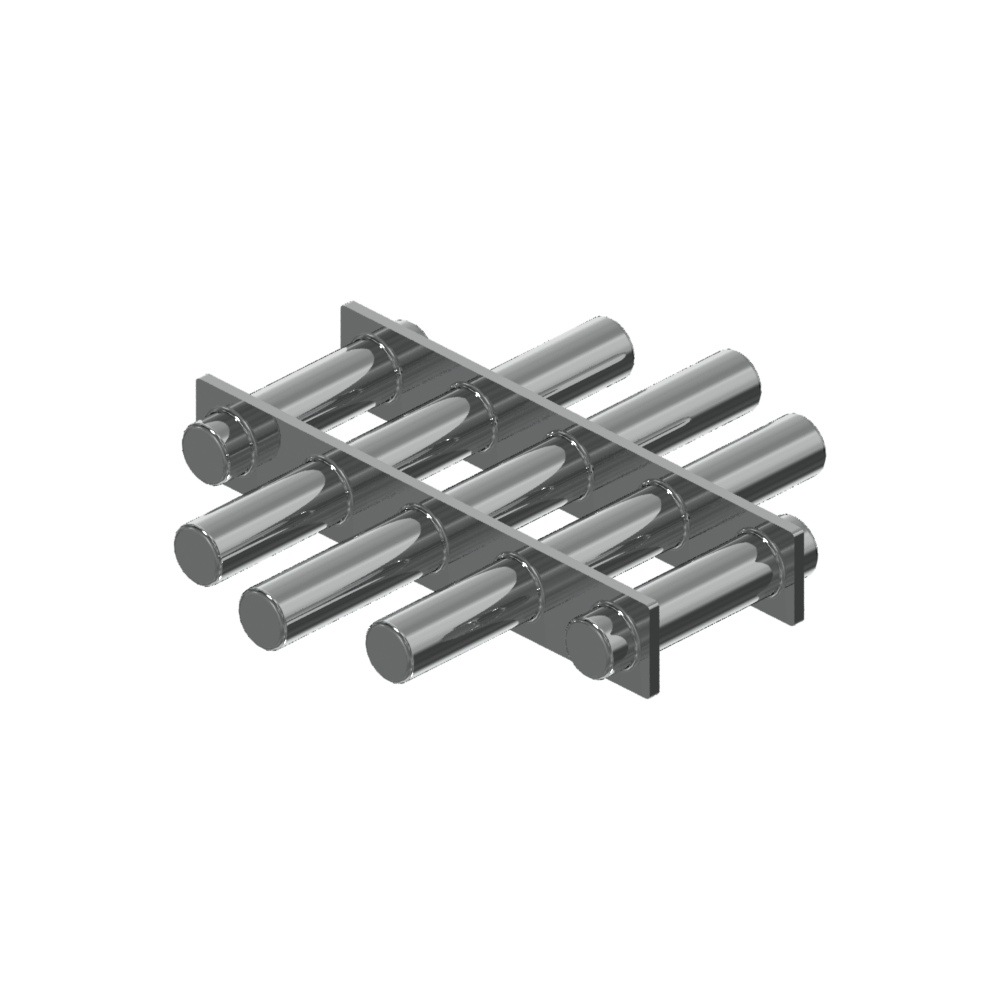

Grid Separator GS0100

Ideal for the removal of ferrous and paramagnetic particulates from a range of dry free flowing products, and therefore suitable for filtration of products within the food, chemical, pharmaceutical, ceramic, animal feed, recycling and gas and oil industries, our Grid Separator is a fully bespoke product and can be designed to fit any size or shape of application.

As product flows past the powerful magnetic bars, ferrous particles as small as 30 microns and tiny paramagnetic particles such as stainless steel scrapings are filtered out. These very fine ferrous and stainless steel particles are smaller than can be detected with a metal detector.

To clean the Grid Separator, remove the magnet from its operational position, and manually wipe each bar to remove the contaminant. The advantage of this separator is that it can be made to much higher strengths (up to 12000 gauss) depending on the required application. However, manual cleaning can be a more time consuming process, and where strengths of 9000 gauss or less are required, our Easy Clean Grid Separator can provide a more efficient alternative.

- Magnetic Grid Separator

For advice or a quote, please contact us.

Alternative products:

For information on these alternative products that may be of interest, please click on the Products link in the menu bar.

- Easy Clean Magnetic Grid Separator

- Easy Clean Magnetic Grid Separator Open

- Easy Clean Boxed Magnetic Grid Separator

- Easy Clean Boxed Magnetic Grid Separator Open

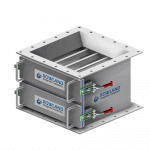

- Easy Clean Double Boxed Magnetic Grid Separator

- Easy Clean Double Boxed Magnetic Grid Separator Open

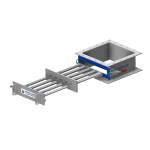

- Easy Clean Boxed Magnetic Grid Separator with Transitions

- Easy Clean Boxed Magnetic Grid Separator with Transitions Open

- Batch Auto Clean Magnetic Boxed Grid Separator

- Constant Flow Auto Clean Magnetic Boxed Grid Separator