Magnetic Conveyor Roller

Product Specification:

- Diameter and length to suit application

- Min. Fe-particle size that can be caught 0.2mm

- Max. operating temperature 60 °C

- Fixed or removable shaft

- Rubber lagged cover

- Field strength (flux density) roller surface (±5%) 3500 or 7000 gauss

Product Information:

Magnetic Conveyor Roller MR3010

The Magnetic Conveyor Roller is a powerful magnetic head roller for installation at the discharge end of a conveyor belt system and is ideal for the removal of ferrous particulates from a range of products within the food, chemical, pharmaceutical, ceramic, animal feed and recycling industries.

The Magnetic Conveyor Roller can be manufactured to any diameter and length required and can be made to strengths of up to 7000 gauss.

As product flows over the magnetic roller at the end of the conveyor system, the contaminant binds to the magnet. As the roller rotates, the contamination is moved underneath to where the magnetic area ends, causing the contaminant to fall off, while the product continues onto the next stage of the production process. The magnetic roller can extract ferrous particles as small as 0.2mm.

The Magnetic Conveyor Roller is low maintenance and highly efficient as it offers continuous removal of contaminant without the need to stop the production process for cleaning.

For advice or a quote, please contact us.

Alternative products:

For information on these alternative products that may be of interest, please click on the Products link in the menu bar.

- Magnetic Plate

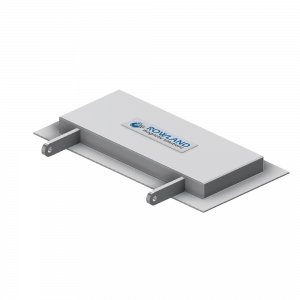

- Hinged Magnetic Plate

- Magnetic Tube